Manufacturing Services

Manufacturing Services

Services

The Center for Additive Manufacturing and Logistics can provide fabrication and prototyping services for both internal NC State projects and external customers on a limited basis. Polymer and metal-based additive technologies are available.

Internal NC State Projects

Instructions:

- The form needs to be signed by the project PI and your department’s accounts manager

- Have an approved budget amount

External Customers

Instructions:

- The form must be signed by both the client and NC State

Direct Metal Additive Manufacturing

All of our direct metal processing activities take place in our ITAR Compliant lab space, including any necessary cleaning/finishing operations.

Our Direct Metal Additive Manufacturing Machines include:

- EBM S12 by Arcam (GE) | 2003

- EBM A2 by Arcam (GE) | 2007

- EBM Q10+ by Arcam (GE) | 2016

- DMLS EOSINT M280 by EOS | 2013

- DMLM Mlab R1 By Concept Laser (GE) | 2018

- DMLM Titanium S by Aurora Labs | 2019

- Arcast Gas Atomizer | 2021

S-Titanium Pro

The S-Titanium Pro by Aurora Labs is a laser powder bed fusion system developed for materials research. The build envelope is 200 x 200 x 250 mm with a 350W CO₂. The s-Titanium Pro has three powder magazines that allows for mixing of materials or gradient materials.

EBM by Arcam

CAMAL acquired the first Electron Beam Melting machine in 2003, which was the first commercial machine that Arcam sold. The S12 and the A2 have been modified with small build chambers (100 mm in diameter by 140 mm tall) and are primarily used for process parameter development for new alloys. These machines have furthermore been modified with additional ports housing research instrumentation. The Q10+ has a build envelope of 200 x 200 x 180 mm and is equipped with the layercam. All three EBM machines have been retrofitted with backscatter detectors developed in-house.

EOSINT M280

The EOSINT M280 is a standard DMLS machine with a build envelope of 250 x 250 x 325 mm and a 200W fiber laser.

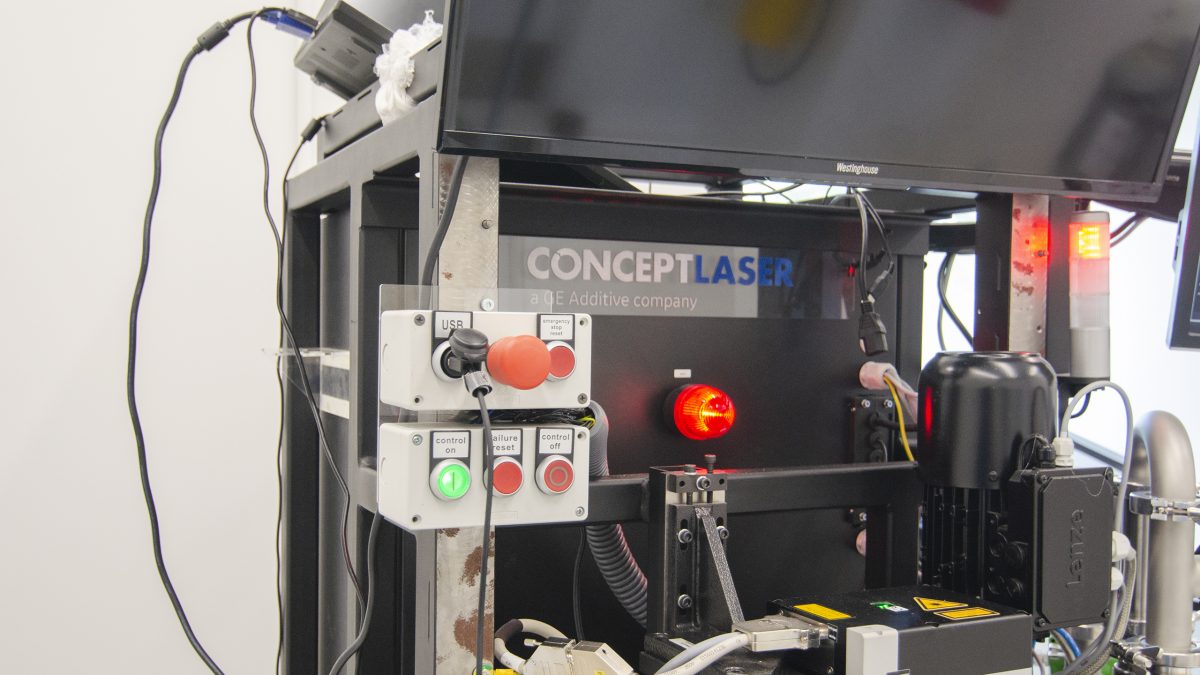

Concept Laser Mlab R

The Mlab R by Concept Laser (GE) has a build envelope of 90 x 90 x 80 mm and a 100 W fiber laser. The R-version comes with the glovebox to allow for handling of reactive materials.

Gas Atomizer

The Gas Atomizer by Arcast is a pilot scale atomizer that will produce approximately 1 kg of powder per run. The atomizer offers four different melting modes and allows us to produce custom powder alloys for metal additive manufacturing processes.

Explore CAMAL

Try out our interactive virtual tour to explore CAMAL’s Direct Metal Additive Manufacturing spaces and resources.

Polymer Additive Manufacturing

Our polymer machines provide us with excellent resources for rapidly producing functional models and training Edward P. Fitts Department of Industrial and Systems Engineering students in the basics of additive manufacturing in an affordable way.

Polymer Additive Manufacturing Machines include:

- Formlabs Form 2 & 3 SLA 3D Printers

- Objet Connex 350 Material Jetting 3D Printer

- HP Jet Fusion 580 Color 3D Printer

- ProJet 260C Color 3D printer

- Markforged Mark 2 FDM 3D Printer

- Nine Stratasys FDM 3D Printers

HP Jet Fusion 580 3D Printer

The Jet Fusion 580 showcases the ability of binder jetting technology, printing full-color functional parts with strong mechanical properties. The Jet Fusion 580 deposits 80-micron-thick layers of nylon 12 powder then uses printheads to selectively add binder agent and ink before curing with a fusing lamp. The 1200 dpi printheads provide even higher resolution in the x and y directions, with each jetted droplet equivalent to 22 microns, or about half the cross section of a human hair. Through this highly accurate process, the Jet Fusion 580 produces stunning models requiring no support structures and minimal post-processing in a matter of hours.

Objet Connex350 Polyjet Printer

Using PolyJet multi-material 3D printing technology, the Connex350 can create complex models within hours. It uses a material jetting printhead and UV curing lamp to print parts in photopolymer resin. With its 350 × 350 × 200 mm build tray and 16-micron resolution, the Connex350 provides the power to prototype complex, detailed, assembled products in a variety of materials. Using the Digital Materials mode it is possible to print in blends of two different photopolymer resins, allowing for as many as 14 unique composite materials to be printed simultaneously in a single part. This eliminates the need for time-consuming assembly and allows for the creation of multi-material parts which would be impossible by most other additive manufacturing methods.

FormLabs

There are three FormLabs machines at CAMAL which use very different additive manufacturing processes; these are the Form 2, Form 3, and Fuse 1.

The Form 2 and Form 3 utilize a vat photopolymerization process known as stereolithography, or SLA. Using a high-power laser to selectively polymerize photopolymer resin, the Form 2 and Form 3 quickly build models on an upside-down build platform. With a catalogue of 32 unique photopolymer resins, FormLabs’ SLA printers are an attractive option for printing parts with material properties that cannot be replicated by most other additive manufacturing methods. The Form 3 has a build envelope of 14.5 x 14.5 x 18.5 cm, and its maximum resolution of 25 microns in the x, y, and z directions ensures dimensional accuracy with smooth surface finish. These printers are paired with the Form Wash and Form Cure, automated post-processing stations which tailor the cleaning and curing processes to each printable resin. The Form Wash cleans parts within minutes of printing completion, and the Form Cure station ensures that parts are cured to achieve optimal mechanical properties in 30 minutes or less.

The Fuse 1 by FormLabs expands their laser technologies to include Selective Laser Sintering, or SLS. Offering both Nylon 12 and Nylon 11, the Fuse 1 uses a laser to selectively sinter 110-micron-thick layers of nylon powder together. This process produces parts with high strength, high durability, and smooth surface finish, and the support-free process means minimal post-processing. The 200 micron resolution and 16.5 x 16.5 x 30 cm build volume accommodate large, highly-detailed parts, and the interchangeable build chambers allow for successive prints with no wait in between. The accompanying Fuse Sift station offers all of the tools required for easy part cleaning and recycling of nylon powder. The Fuse 1 is a great choice for anyone requiring functional prototypes for high strength applications.

Projet 260C

The ProJet 260C uses a binder jetting process to produce full-color models. The ProJet 260C offers one of the fastest and most affordable options for producing colored prototypes by using widely-available materials. Its gypsum powder core material is binded with a biocompatible lactam chemical commonly used in inkjet cartridges, and color is added using common HP inkjet cartridges. Once parts have been post-processed with a strengthening agent, they are suitable for applications such as concept modeling, ergonomics, and assembly visualization.

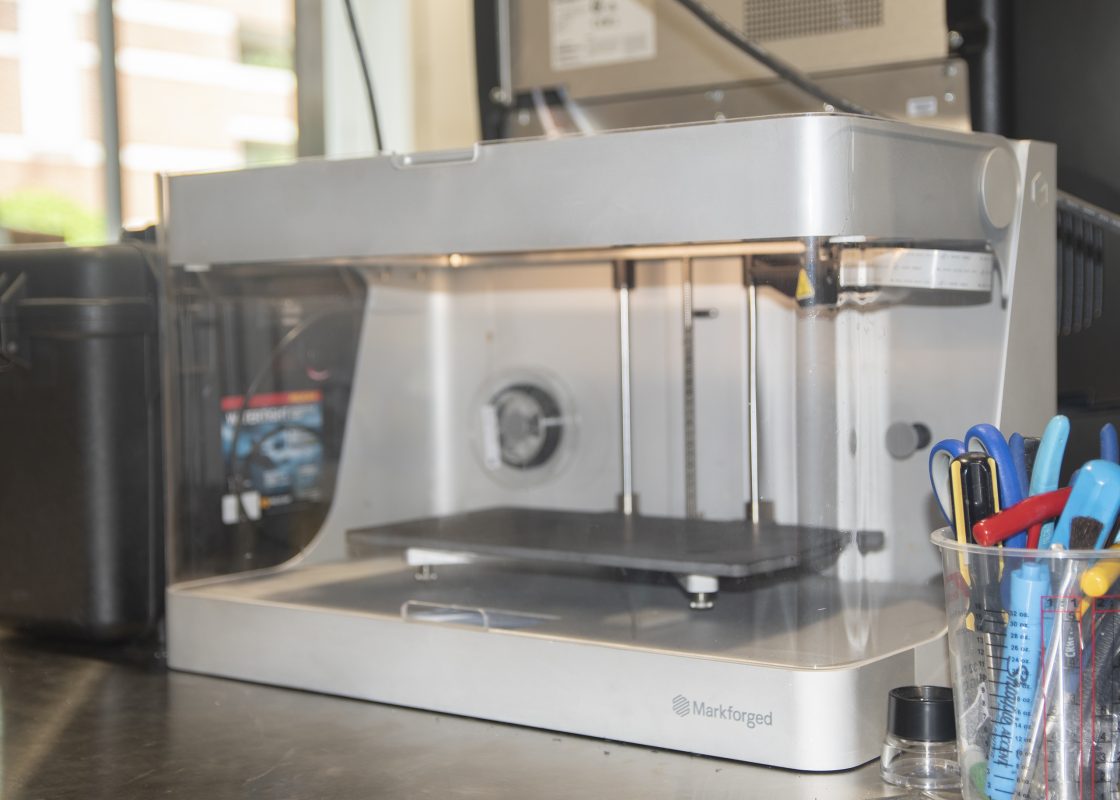

Markforged Mark 2

Offering the strongest parts available from any of CAMAL’s polymer additive manufacturing machines, the Markforged Mark 2 is a Fused Deposition Modeling (FDM) machine which can create aluminum-strength parts on a desktop. Its signature Onyx material, a blend of nylon and carbon fiber, may be reinforced with a variety of fiber materials – nylon, carbon fiber, kevlar, or fiberglass. With the ability to customize infill structures, fiber patterns, and part density, the Mark 2 allows for mechanical properties to be tailored to the specific needs of a part. The Mark 2 leaves parts with a superior, smooth surface finish to minimize post-processing and increase rapid prototyping efficiency.

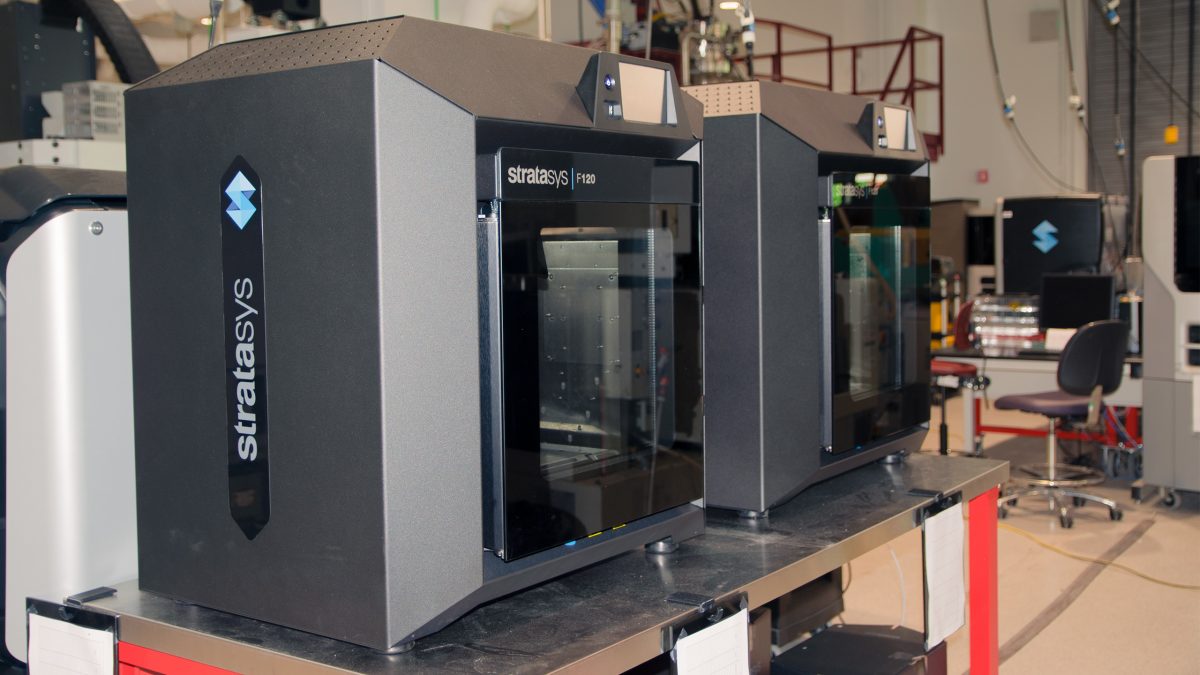

Stratasys

Over the past 20 years, Stratasys had produced a variety of Fused Deposition Modeling (FDM) printers, eight of which can be found at CAMAL. These machines allow ISE students to get hands-on experience with 3D printing by using affordable materials and intuitive software. These machines utilize dissolvable support material, simplifying post-processing to the use of a support removal bath.

Three uPrint SE Plus printers offer printing in ABS in an 8 x 8 x 6 in. build volume. The larger Dimension 1200 bst also prints in ABS but provides a significantly larger build volume at 10 x 10 x 12 in.

New to CAMAL are four machines from Stratasys’ F123 series. These machines allow for greater customization of infill and supports than previous generation Stratasys FDM printers and even allow for feature-based customization of CAD models. The two F120 printers can print in both ABS-M30 and ASA materials and have a build volume of 10 x 10 x 10 in. The F170 provides the same build volume but adds PLA, TPU, and ABS-CF10 to it’s material options. The largest FDM machine at CAMAL is the F370 with a 14 x 10 x 14 in. build volume. The F370 has even more material options than the F170, adding PC-ABS and Diran materials. The Insight software which is exclusively compatible with the F370 allows for fine-tuning of slicing and toolpaths to ensure that the F370 can produce the very best part that Stratasys’ FDM machines have to offer.

Explore CAMAL

Try out our interactive virtual tour to explore CAMAL’s Polymer Manufacturing spaces and resources.

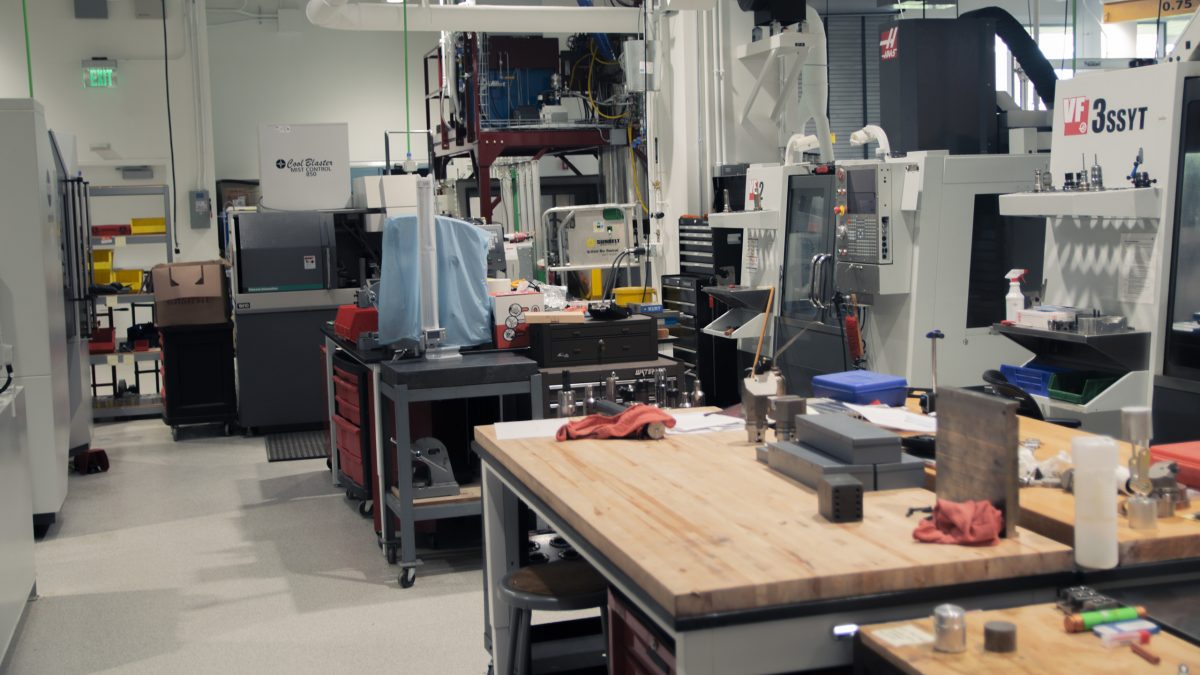

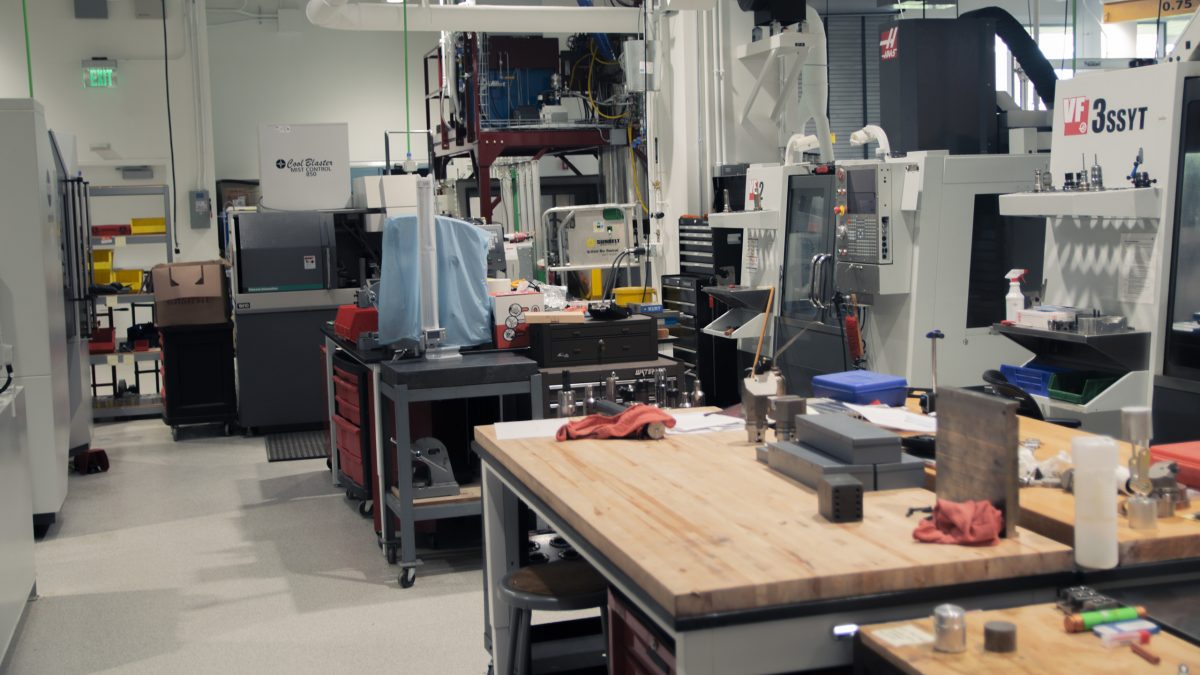

CNC Machining

Producing precise metal parts using CNC machining equipment of the highest capability is essential.

CNC Machining Machines include:

- HAAS VF 2 Vertical Machining Center

- HAAS VF 3ssyt Vertical Macining Center

- Mazak Integrex i-100ST

- HAAS Multigrind CA 5 Axis Grinding Center

- Citizen Machinery Cincom L20

- Mitsubishi FA10S CNC Wire EDM

- Mitutoyo Quick Scope QS-L2010Z/AFC

HAAS VF 3ssyt Vertical Machining Center

Our HAAS VF 3ssyt has a 5 axis machining center that has supported our metals work for several years. It has a travel of 40″ X 26″ X 25″ and a RPM range of 12000. It also includes a 24 position tool changer, 4th axis rotary table, and 4th/5th axis trunnion.

Citizen Machinery Cincom L20

The Citizen Machinery Cincom L20 gives us screw making capability that is particularly applicable to our medical research activities. This machine has a maximum machining diameter of .78″ and length of 7.87″. The main spindle has a speed of 10000 RPM and the rotary spindle has a speed of 7500 RPM. Additionally, this machine includes thread whirling and a cool blaster high pressure coolant system.

HAAS VF 2 Vertical Machining Center

The HAAS VF 2 Vertical Machining Center has a travel of 30″ X 16″ X 20″ and a RPM range of 8000. It also includes a 20 position tool changer, cat 40 taper, and 4th axis rotary table.

Mazak Integrex i-100ST

Our Mazak Integrex i-100ST combines the capabilities of a high-powered turning center and full-function machining center to produce parts in single setups. With full 5-axis capability, this machine easily processes parts effortlessly. It has a 6″ main and secondary spindle with an RPM of 6000. Additionally, it has a magazine capacity of 36, a maximum machining diameter of 19.670″. and length of 33.620″.

HAAS Multigrind CA 5 Axis Grinding Center

The HAAS Multigrind CA 5 Axis Grinding Center has a travel of 24.8″ X 15.83″ X 16.92″ and a RPM range of 8000. It also has a maximum diameter of 10.2″ and length of 21.6″.

FA 108 Wire EDM

High speed and large capacity Wire EDM works well for complex shapes and intricate contours and cavities.

Explore CAMAL

Try out our interactive virtual tour to explore CAMAL’s CNC Machining spaces and resources.