Media Resources | CAMAL

Media Resources

Media Contacts

Are you looking for specific information about CAMAL? Talk with a member of our media relations team.

Robert Lasson

Director of Creative Services

rrlasson@ncsu.edu

919.515.3016

Chris Rock

Manager for Outreach and Customer Support

cdrock@ncsu.edu

919.515.6419

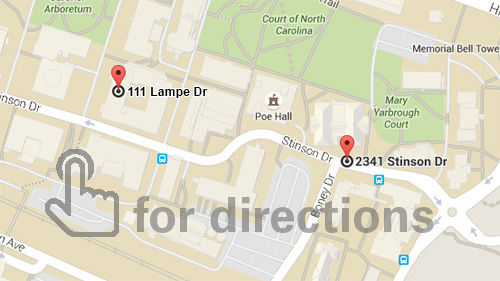

Directions and Parking

You can get visitor parking information at the visitor booth located on Katharine Stinson Dr. (see map). Staff can give you directions and a map which shows valid parking spaces.

Main Campus Booth:

Stinson Drive off the Pullen Road roundabout.

7:00 a.m. – 5:00 p.m., Monday through Friday.

919-515-3205 or email them.

For more information about parking on NC State’s campus, please visit the NC State’s visitor parking.

CAMAL Logos

The CAMAL logo uses fonts from the Univers family. But, they do not need to be loaded on your system.

- The JPG files should be used for PowerPoint, Microsoft Office documents and the web

- The PNG files offer a transparent background and are good for student research posters

- The EPS (vector) files are the only logos that should be used for print because vector files will print cleanly at any size

If you need some other color variation or file formats of our logo, please contact our Director of Creative Services, Robert Lasson | rrlasson@ncsu.edu | 919.515.3016.

NC State University Logos

For information about NC State University’s brand guidelines, go to brand.ncsu.edu.

- All Print (CMYK) Logos (ZIP 3.4MB)

- All Screen (RGB) Logos (ZIP 3.7MB)

- All Microsoft Office logos (ZIP 750KB)

CAMAL Descriptions

If you need more detailed information, please contact our Director of Creative Services, Robert Lasson | rrlasson@ncsu.edu | 919.515.3016.

50 Words or Less Description

The mission of the Center for Additive Manufacturing and Logistics (CAMAL) is to be a pioneer in the areas of research and development of rapid prototyping and advanced manufacturing. This also includes the global management of additive manufacturing supply chain logistics.

100 Words or Less Description

The mission of the Center for Additive Manufacturing and Logistics (CAMAL) is to be a pioneer in the areas of research and development of rapid prototyping and advanced manufacturing. This also includes the global management of additive manufacturing supply chain logistics.

CAMAL started in 2014 with the support of the Edward P. Fitts Department of Industrial and Systems Engineering (ISE) and NC State University. The center was born from ISE’s strong manufacturing tradition, a legacy that included a pre-eminent Furniture Manufacturing and Management Center and the groundbreaking Rapid Prototyping Lab.

Full Description

The mission of the Center for Additive Manufacturing and Logistics (CAMAL) is to be a pioneer in the areas of research and development of rapid prototyping and advanced manufacturing. This also includes the global management of additive manufacturing supply chain logistics. CAMAL currently has a rich and diverse research portfolio in:

- Biomedical

- Hybrid manufacturing

- Supply chain and logistics

- Material development

CAMAL also benefits from being part of the world-renowned College of Engineering at NC State University. As a result, we have access to the best and brightest engineering students. We work with both graduate and undergraduate students in:

- Industrial and Systems Engineering

- Electrical and Computer Engineering

- Mechanical Engineering

- Biomedical Engineering

- Materials Science

- Integrated Manufacturing Systems Engineering

Faculty Photos and Bios

These are 500 x 500 pixel images of our faculty members. To get a copy, click on the image, right-click on the full-sized version and then select “Save Image As …”. If you need an even higher resolution version, please contact our Director of Creative Services, Robert Lasson | rrlasson@ncsu.edu | 919.515.3016.

Ola Harrysson is the Director of CAMAL and is currently involved in research with numerous industries as well as providing faculty and students with prototyping services. Most of his research involves additive manufacturing, specifically medical applications.

Russell King is the Manager of Logistics Research for CAMAL and is an Alumni Distinguished Graduate Professor, Alumni Distinguished Undergraduate Professor and is a Fellow of the Institute of Industrial and Systems Engineers. His research interests include logistics, scheduling and inventory control for additive manufacturing and military systems under risk.

Harvey West is the Manager for Material Testing and Characterization for CAMAL and is responsible for the characterization and testing of metal and polymer parts fabricated by additive manufacturing. He manages labs equipped for chemical analysis, static and fatigue testing, metallography and particle size analysis.

Social Media Channels

CAMAL has many active social media channels. Click on the icons to visit our pages and while you’re there LIKE, FOLLOW, JOIN or SUBSCRIBE to us!