In continuation of my first post on this subject, the first three of tensile specimens were put to the test this past week. With the assistance of Dr. Harvey West, I subjected the specimens to a tensile test until failure. For the set up I chose to apply a 0.1 in/min displacement of the load. I also used a 5000 lb capacity load cell to withstand the loads I wished to apply and a universal joint to compensate for any warping that might have occurred in previous steps. (i.e. in the printing process or in the acetone bath)

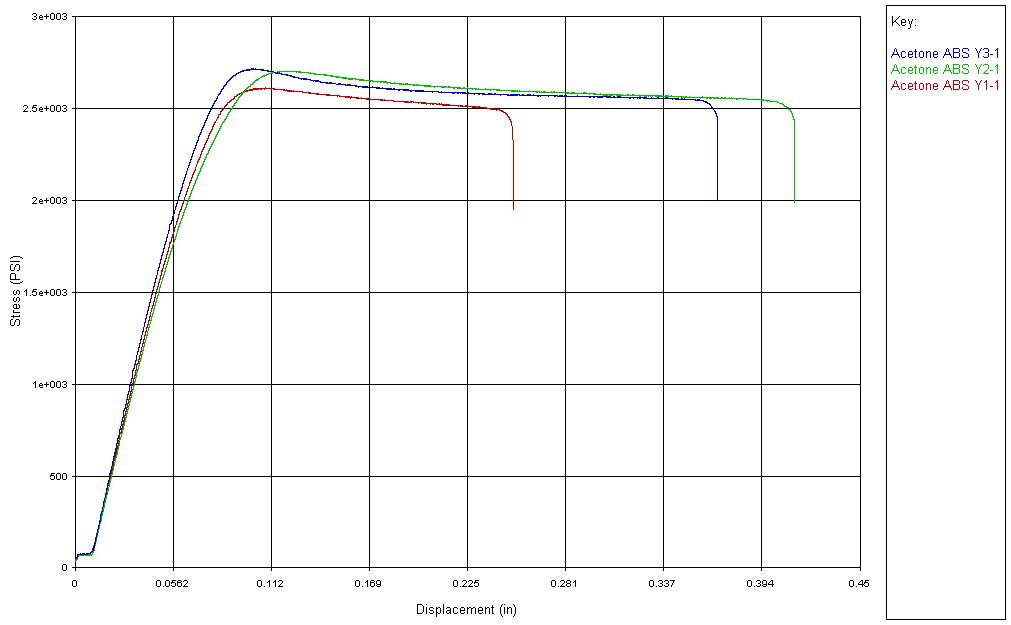

As hypothesized, I have seen that there is a noticeable difference between the parts subjected to the acetone treatment versus those that weren’t subjected to any treatment (Y1-1). From the preliminary testing, I even saw that there was also a difference between the specimens that were exposed to high-temperature testing (Y3-1) versus low-temperature testing (Y2-1). While the peak loads do not very much there appears to be a difference in the area under the load-displacement curves.

The initial results look promising, however , I will be continuing to test the remaining samples that I already have and I will post more results as they are acquired.